- +65 96273596

- sales@bizpoint-intl.com

Warehouse Automation is a fully integrated solution which helps to streamline and automate all operations to support one of the largest Office Supplies solution provider in Singapore.

The key objective for the project is to develop and deploy a new robotic warehousing capability :

The scope and key deliverables of the project will include :

(1) Increased stocking and order picking productivity

(2) Increased order accuracy

(3) Enhanced order fulfilment rates

(4) Inventory Accuracy and Security

(5) Space Optmisation

(6) Greater Flexibility and Scalability

(7) Electricity Savings

(8) Enhanced Quality of Life

(9) Reduced Noise level and cleanliness

(10) Reduced Training Time

(11) No downtime and built-in redundancy

(12) The 'Wow' Factor to Customers and all Stakeholders

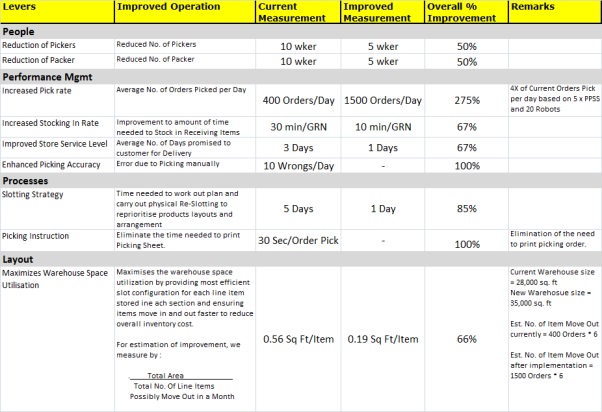

Here are some Quantitative Improvements :